FTP Sewatama Melak

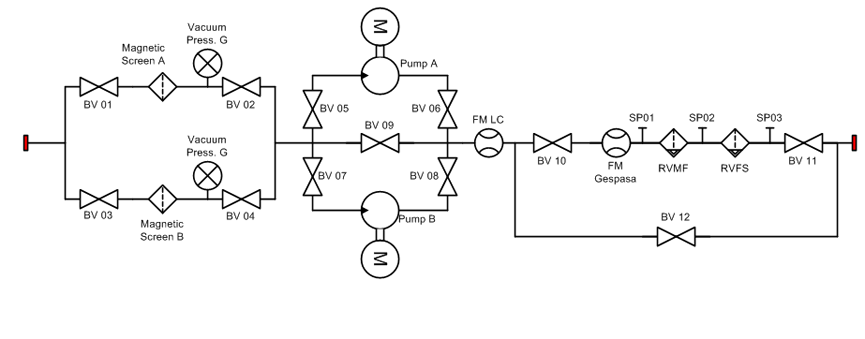

This Filter system is designed to remove solid contaminants such as dirt, rust, scale, and other solid materials from a hydrocarbon fuel stream. Coalescer and water separator vessel set up as a filter / water separator (RVFS) will remove emulsified free water and solids from diesel fuel, gasoline, and either hydrocarbon streams. When equipped with filter / water separator filters, water can be drained and removed by the RVFS sump.

The Fuel Filtration Module is designed to be used as:

- Zinga pre filter element to remove metal contaminant that bigger than 150 micron. This filter element will avoid big solid particle contaminant to come into the pump.

- RVMF - 3 to remove solid contaminants such as dirt, rust scale, sand and other solid materials from hydrocarbon flow stream.

- RVFS – 3 Filter separator to remove emulsified, free and entrained water and solids from liquid hydrocarbon flow streams.

For this filtration system there are 2 pumps that working alternately. From tank, fuel will be sucked by pump to be streamed via magnetic strainer. From the pump, the diesel fuel will flowing through flow meter and then be filtered by RVFS and RVMF.

FTP Sewatama Melak is packaged in rigid and light frame. The rigid and light frame is a simple frame to increase stability and move ability. Every components of FTP Sewatama Melak is attached at this frame, the components consists of 2 sets of V15 Pump assy, 2 set of magnetic strainer, 2 kind of flow meter, filter housing for RVMF and RVFS.

There is a by pass line in this system as well in order to by pass the fuel flow if the end user want to transfer the fuel (by outsource pump) and the fuel doesn’t need to filtered by RVMF-3 and RVFS-3. The operation will be ecxplained at the next chapter.

Main Equipments

Magnetic Screen as a Preliminary Filtration

The preliminary filtration process is done by a magnetic screen filter with standard mesh 100 mesh (150 microns). It contains 2 (two) magnets with polarizing steel end plates and 3 (three) wire cloth elements.

Vane pump series V15

Designed and precision built for efficient transfer of a variety of liquids over a wide range of viscosities with lubricating or non – lubricating characteristic.

| Specifications | ||

|---|---|---|

| Max Flow | : | Up to 164.45 L /min |

| Max Differential Pressure |

: | Up to 1100 kPa |

| Viscosity range | : | <1 up to 10,000 cSt |

| Temperatures | : | Up to 100°C as standard |

Features

- Quiet operation

- High overall efficiency

- Low maintenance – long life

- Internal wearing parts replaceable without removing pump from piping.

- Variable mounting options. 90° or 180° port configuration

- Double ended shaft option

- Direct coupling to synchronous electric motors, speed variations, PTO’s or engine driven

- Facility for close coupled hydraulic motor connection

- Belt drives

- Lightweight – Robust – Compact

- Positively actuated vanes

- Integral adjustable relief valve

- Mechanical Seals as standard

Flow Meter LCM-10

| Specifications | ||

|---|---|---|

| Accuracy | : | 0.2% |

| Repeatability | : | 0.05% |

| Standard Measurement | : | Unit Liter / US Gallon / imperial Gallon |

| Max Working Temperature |

: | ( -40?C to 70?C ) |

| Meter Body | : | Aluminum , Cast Iron , Steel , Stainless Steel available |

| Connections | : | ANSI Flange, NPT , BSPT , Slip Woled Available |

| Capacity | : | 550 Lpm (150 GPM) (free flow) |

| Max. Pressure | : | 10 Bar / 150 PSI |

| Type | : | Direct Reading |

RVMF-3

This filters are utilized as first stage filtration for heavily contaminated fuel of hydrocarbon fluids to protect filter separators and any mechanical components installed in the piping system downstream. To achieve good filtration performance, racor combines media composed of cellulose, synthetic and glass fibers. This media is pleated in several unique ways, and then utilized in our pre – filter elements. This offers operators longer life and higher contaminant holding capacity.

| Specifications | ||

|---|---|---|

| Inlet,and outlet ports | : | ANSI Flange 2” #150 RF |

| Vent and relief ports | : | ¾ in NPT |

| Water level gauge Ports |

: | ½ in NPT |

| Differential gauge ports |

: | 1/8 in NPT |

| Design Pressure and Temperature |

: | 250 PSI @ 250°F,(17 bar @ 121°C) |

| Pressure Drop – clean | : | 2 PSID (0.14 bar) |

| Pressure drop / Element Change out |

: | 25 PSID ( 1.73 bar) |

| Height | : | 2229 mm |

| Width | : | 385 mm |

| Depth | : | 355 mm |

| Dry weight | : | 112 kg |

| Overhead service clearance |

: | 1194 mm |

| Filter Element | : | HFP – 43605 (1 set) |

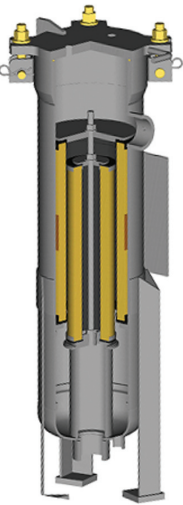

Coalescer and Water Separator Filter (RVFS – 3)

The RVFS Series filter vessels are designed to be used for diesel fuel dispensing, fuel transfer, and large engine applications. Their prime function is to remove water and dirt to reduce contamination levels, prolong engineer life and keep engine applications running. Element Racor’s HOCP and HSP coalescer and separator series the coalescer cartridge provides primary filtration as well as coalescing free water. The clean fuel passes through the separator barrier and into the outlet of the housing. The coalesced water droplets are repelled by the hydrophobic barrier and collect in the sump of the housing. The sump should be drained daily. Features:

- carbon steel construction; other materials available.

- 250 psi ASME Code, Section VII construction, stamped and certified.

- Yellow zinc – pleated swing bolt closure.

- Buna-N o-ring seal cover.

- Interior: epoxy-coated MIL – C4556 E.

- Exterior: prime coated.

- Knife – edge cartridge mounting seals.

| Specifications | ||

|---|---|---|

| Inlet,and outlet ports | : | ANSI Flange 2” #150 RF |

| Vent and relief ports | : | ¾ in NPT |

| Water level gauge Ports |

: | ½ in NPT |

| Differential gauge ports |

: | 1/8 in NPT |

| Design Pressure and Temperature |

: | 250 PSI @ 250°F,(17 bar @ 121°C) |

| Pressure Drop – clean | : | 2 PSID (0.14 bar) |

| Pressure drop / Element Change out |

: | 25 PSID ( 1.73 bar) |

| Height | : | 2185 mm |

| Width | : | 285 mm |

| Depth | : | 255 mm |

| Dry weight | : | 112 kg |

| Overhead service clearance |

: | 1194 mm |

| Element Coalescer | : | HOCP – 44810 (1 set) |

Differential Pressure Gauge

The Ashcroft 1130 differential pressure gauge is an economical means for measuring pressure between two independent pressure source. Used on process monitoring or control, the unit’s system design permits a small volume of media migration intended for air, hydraulic oil and non-corrosive applications.

| Specifications | ||

|---|---|---|

| Model,Number | : | 1130 |

| Accuracy (Ascending): | : | ±2% |

| Migration | : | Minor |

| Ranges | : | 0,5 psid up to 150 psid |

| Maximum Static Pressure |

: | 3000 psi (6000 psi for SS) |

| Actuator | : | Piston |

| Case Material | : | Stainless steel |

| Dial Size | : | 2? |

| Maximum Process Temp | : | 175°F (80°C) |

| Body Materials | : | Aluminum (F), brass (A), stainless steel (SS) |

| O-Rings / Diaphragm | : | Buna-N |

| Connection Size (Female) |

: | ¼,NPT |

| Connection Location: | : | In-Line (S), Lower (L), Back (B) |

Air Eliminator

Armstrong stainless steel free floating level air vents is to provide positive venting of air / gases under pressure. The body and cap and all working parts of the No. 11-AV is made of high strength, corrosion resistant stainless steel. Body and caps are welded together to form a permanently sealed, tamper proof unit with no gaskets. Elliptical floats and high leverage provide up to 115 SCFM capacity for these compact air/gas vents. Lever action is guided to assure proper seating of the valve under all operating conditions.

| Specifications | ||

|---|---|---|

| Model,No. | : | 11-AV |

| Valve and Seat | : | Hardened chrome steel – 17 – 4PH |

| Leverage System | : | 303/304 Stainless Steel |

| Float | : | 304 Stainless Steal |

| Body and Cap | : | Sealed Stainless Steel 304 - L |

| Max. Allow. Pressure,(Vessel Design) |

: | 500 psig @ 100°F (34 bar @ 38°C),440 psig @ 500°F (30 bar @ 260°C) |