Workshop Oil Facility

Auto lubrication for porshce workshop is designed to make lubricant for porshce’s cars can be more clean, safety and eco friendly, also operator doesn’t need to make a big effort when doing the unit maintenance. With magnetic strainer that installed in this lubrication system will make sure that the lubricant is free from contaminants and can meet with the specification that porsche’s need.

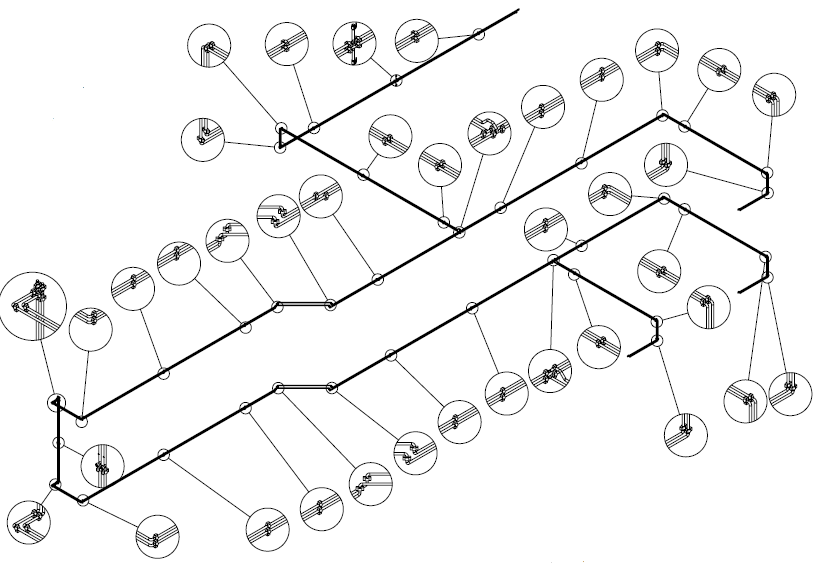

There are two kind of oil that used in this lubrication process, hydraulic and engine oil. For each oil used different pump to maintain cleanliness in the oil line. For hydraulic and engine oil have 5 working bay for each oil lubricant (total 10 working bay). Lubrication system in porsche use flexible coupling to connecting pipe, total flexible coupling that use in this project is 92.

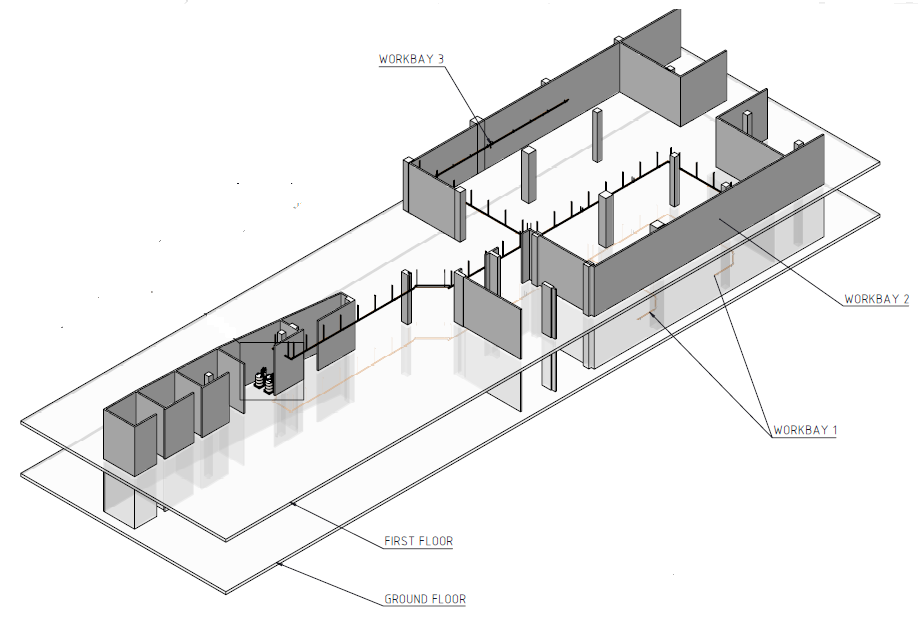

Installation for workshop oil facility divide into two floor, on the first floor there are oil room (2 pump), workbay 2 and workbay 3, and for g round floor there are workbay 1.

Main Equipment

Bare Pumps

Delivers a uniform six gallons of product per minute free delivery. 5 : 1 pressure ratio stub pump had specification as below :

| Spesifications | ||

|---|---|---|

| Ratio | : | 5:1 |

| Drum Size | : | Stub / universal |

| Air inlet | : | 1/4 “ NPT |

| Material outlet | : | ½ “ NPT |

| Output | : | 6 GPM |

| Min. Air Pressure | : | 40 PSI |

| Max. Air Pressure | : | 200 PSI |

| Max. Output Pressure | : | Max. Output Pressure |

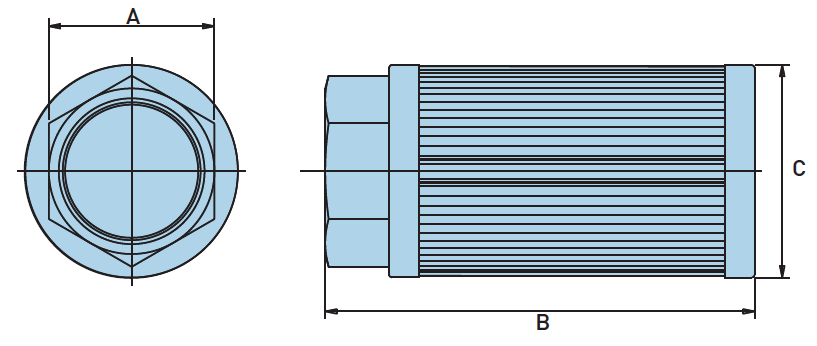

Magnetic Suction Strainer

Parkers magnetic suction strainers are available in sizes ranging from one to three inches. All sizes are standard with 30 mesh screen (560 micron).

| Spesifications | ||

|---|---|---|

| Part Number | : | 936550 |

| NPT Connection | : | 3.00" |

| Flow GPM (LPM) | : | 100 (380) |

| Dimensions (inches/mm) | : | |

| A 2.75/69.85 | ||

| B 7.39/187.71 | ||

| C 4.47/113/54 | ||

| Approx. Shipping Weight lbs (kg) | : | 2.22/1.01 |

Service Unit FRC 3/4-D-MIDI

This FRC Filter/Regulator have high flow rate and highly efficient removal of contaminants, with good regulating characteristics and minimal pressure hysteresis.

| Spesifications | ||

|---|---|---|

| Size | : | Midi |

| Condensate drain | : | Manual momentary – contact |

| Grade of filtration,,µm | : | 40 |

| Operating Pressure,,bar | : | 1 up to 16 |

| Pressure regulation,range, bar | : | 0.5 up to 12 |

| Standard nominal,flow rate, l/min | : | 2600 |

| Operating medium | : | Compressed air to ISO 8573-1:2010,Inert gases |

| Note on operating and,pilot medium | : | Lubricated operation possible (subsequently required for,further operation) |

| Medium temperature,,ºC | : | -10 up to 60 |

| Ambient temperature,,ºC | : | -10 up to 60 |

| Product weight, gram | : | 1440 |

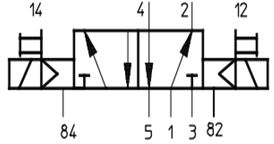

Solenoid Valves

For this project using Solenoid valve Tiger 2000 from festo with tubing connection threads sizes G ¼. With diverse and flexible, side and front mounting this solenoid valve can optimized for increased flow rates without increasing size.

| Spesifications | ||

|---|---|---|

| Description | : | Without,F solenoid,coil1), internal pilot air supply,1),F solenoid coils ? 65 |

| Circuit symbol | : |  |

| Pneumatic connection | : | G ¼ |

| Part No. |

: | 19789 |

| Type | : | JMFH-5-1/4-B |

| Valve function |

: | 5 / 2-way, double solenoid |

| Standard nominal flow rate, l/min |

: | 1600 |

| Operating Pressure, bar |

: | 2 up to 10 |

| Ambient temperature |

: | -5 up to 40 |

| Temperature of medium |

: | -10 up to 60 |

Medium Pressure Filter

| Features | Advantages | Benefits |

|---|---|---|

| 800,psi fatigue rating,(eight times that of a spin-on) |

|

|

| Diametral(side) seal between head and bowl |

|

|

| Dust seal |

Prevents contamination from building up on bowl/head threads |

Easier service, no galling |

| 40CN-2 meets automotive HF3 standard |

Automotive industry acceptance |

Satisfies specifications without need for further testing and/or approval |

| Cast aluminum head | Low profile, lightweight and durable |

Less weight, smaller envelop and cleaner appearance |

| Standard ecoglass III Elements |

|

|

| Complete performance data disclosure | All pertinent information is provided in an easy-to-compare format |

|

| Visual, electrical or electrical / visual indicators available |

|

|

Ball Valve

| Specification | ||

|---|---|---|

| Valve function |

: | 2 / 2 bistable |

| Type actuation |

: | Manual |

| Standard nominal flow rate, l/min |

: | 21000 |

| Nominal size, mm |

: | 20 |

| Ambient temperature, ºC |

: | -20 up to 180 |

Pressurized Waste Oil Tank

For porsche workshop oil facility project we use oil tank with capacity 20 gallon (75 litter). Model 3614 features a stable, low-profile tank design and large 18 in (457,2 mm) offset bowl with metal filter screen.

For evacuation, the tank can be pressurized by connecting a standard shop airhose, or by using a simple tire chuck. The height is easily adjustable by loosening and tightening a friction-style lock-ring, and a special telescoping tube design eliminates the need to extend the bowl during evacuation.

| Specification | ||

|---|---|---|

| Model | : | 3614 |

| Capacity, gal.(liter) |

: | 20. (75.71) |

| Bowl diameter, in.(mm) |

: | 18. (457,2) |

| Bowl configuration |

: | Offset |

| Reservoir material |

: | Steel |

| Maximum pressure, psi/bar |

: | 1500 / 103.4 |

| Free Delivery, gal./min |

: | 4.0 |

Silencer

Silencers AMTE-M-LH-G1/4 is suitable for reducing noise at the exhaust ports of pneumatic systems.

| Specification | ||

|---|---|---|

| Mounting position | : | Any |

| Noise Level(1) [db(A)] |

: | <95 |

| Flow rate with respect to atmosphere(2) [l/min] |

: | 1000 |

| Product weight |

: | 9.5 |

| Operating Pressure [bar] |

: | 0 up to 10 |

| Note on operating/pilot medium |

: | Lubricated operation possible |

| Ambient temperature |

: | -10 up to 80 |

| Corrosion resistance class (RC3) |

: | 1 |

- 1) Measured at 6 bar with respect to atmosphere at a distance of 1 m

- 2) Measured at P1 = 6 bar

- 3) CRC1: Corrosion resistance class to Festo standard 940 070

Flexible coupling from victaulic

For workshop oil facility project is use flexible coupling style 75. Style 75 is available where moderate pressures are expected or weight considerations are a factor. This coupling is recommended for service up to 500 psi / 3450 kPa depending on size. Housing are cast in two identical pieces in all sizes.